Latest News

19Aug

EcoBoost Diffuser

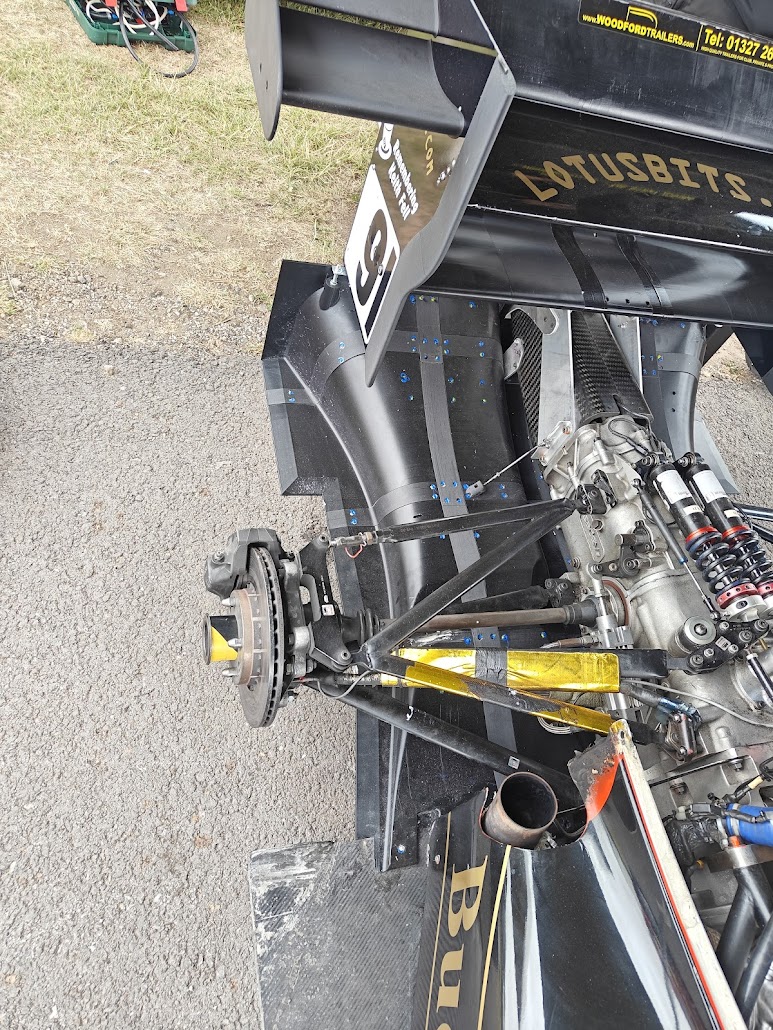

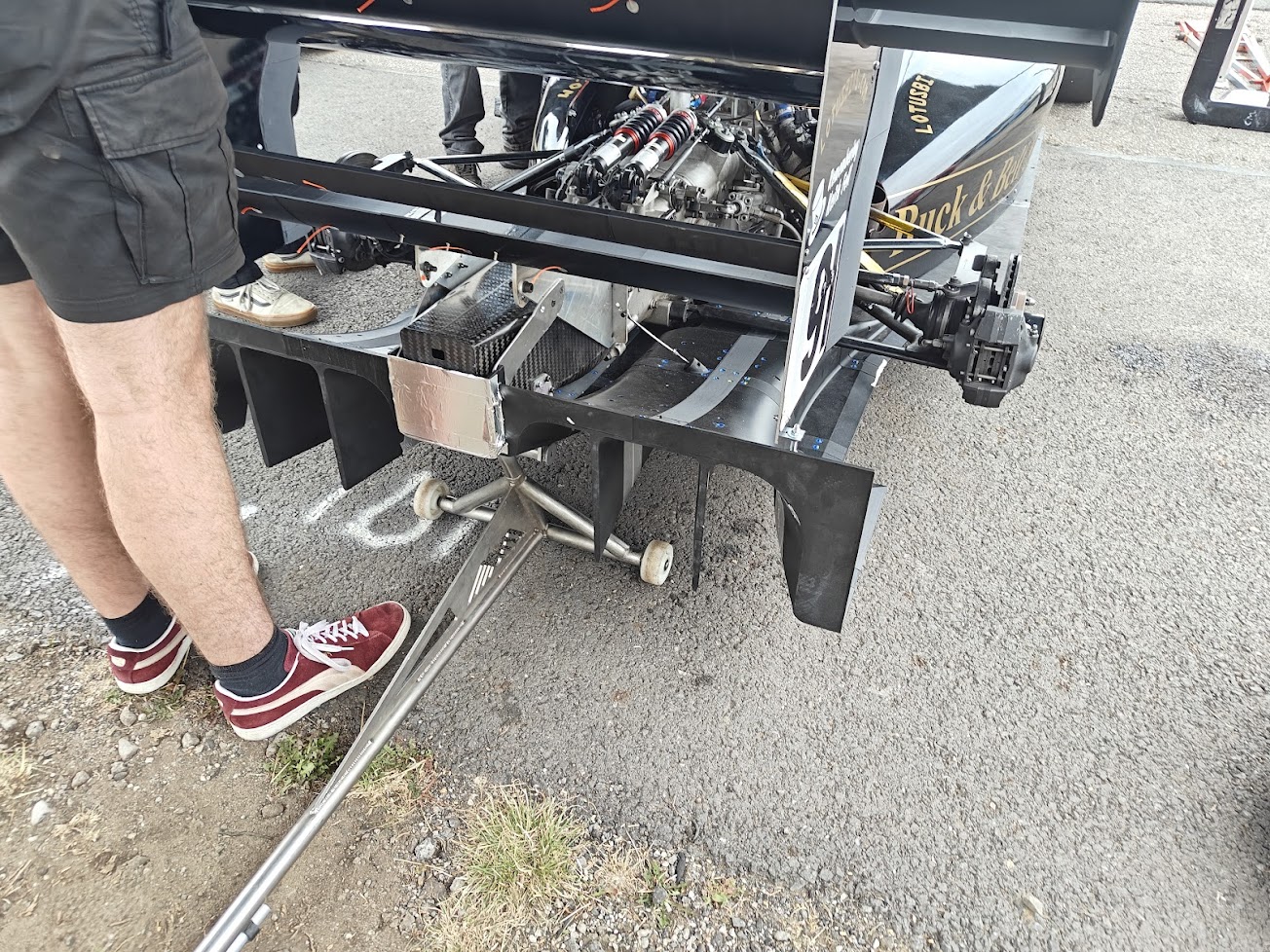

I was really impressed with the 3D printed diffuser that Mike and Cathy were running on their F4 EcoBoost. Mike has clearly spent a lot of time working on the design, and the quality and fit of the parts was really impressive. My only concern was the weight of the finished product, it was printed to withstand knocks and bumps and most of all not to flex when the car was travelling at speed. Hats off to Mike for making a really nice diffuser. I am inspired to have a go at making my own now. I would however rather make the moulds that a composite diffuser would be made from, as that would be far lighter to fit on the car. I'll start working on a few designs in Fusion and see what I can come up with.

18Aug

Double FTD at Blyton

Staying on the Avons meant my times werent going to be comparable to my previous FTD's on both layouts, but I still went fast enough to set FTD on both days, which was good. I was suffering from understeer both days, when turning left, which is partly down to the ageing Avons, and the cool weather, but also in part to the fact that I think I've finally got the floor working properly. With the right angle strip stuck across the join in the two 90 degree sections that make the edge of the floor, I was able to prevent the leading edge from lifting, which meant air was forced in to and forced through the floor, which increases the downforce at the rear. So much so that over the weekend I kept lowering the rear wing angle until it reached the lowest setting I've ever run, and despite still suffering a minor bit of understeer when exiting corners under power, I was getting happier with the aero balance. Had I tried the Pirellis I'm sure the understeer would have dissapeared entirely, as the offside front Avon is now quite badly torn, and wont clean up, and it was on left handers that she didnt want to turn left. And as I was over a second quicker than second place on both days, I simply didnt need to run the Pirellis. The event itself ran very smoothly. It was Yorkshire Motor Clubs first event, and they did a great job. It was my first MSUK event since last year, and I had the car scrutineered by Glenn Stockton. No issues of course. Glynn Sketchly was competing in his 261st event, sadly he was off the pace with an engine that sounded gradually worse over Saturday and he didnt run on Sunday. In my class was the newer F4 EcoBoost, which is undergoing a lot of development at the moment. Running on Pirellis they were gradually closing the gap on Sunday, and both Mike and Cathy managed to go under 60 seconds on their final runs. Great to see them improving, and I look forward to seeing them at their next event. Clive Austin turned up on Sunday, with his Empire, which I was expecting to be my closest rival, but he'd never been before and was 9s slower. The car was hitting the rev limiter as its not geared from long circuits. I think he was impressed with the Mygale, he came across and said "so this is the beast" :D

The event itself ran very smoothly. It was Yorkshire Motor Clubs first event, and they did a great job. It was my first MSUK event since last year, and I had the car scrutineered by Glenn Stockton. No issues of course. Glynn Sketchly was competing in his 261st event, sadly he was off the pace with an engine that sounded gradually worse over Saturday and he didnt run on Sunday. In my class was the newer F4 EcoBoost, which is undergoing a lot of development at the moment. Running on Pirellis they were gradually closing the gap on Sunday, and both Mike and Cathy managed to go under 60 seconds on their final runs. Great to see them improving, and I look forward to seeing them at their next event. Clive Austin turned up on Sunday, with his Empire, which I was expecting to be my closest rival, but he'd never been before and was 9s slower. The car was hitting the rev limiter as its not geared from long circuits. I think he was impressed with the Mygale, he came across and said "so this is the beast" :D

There was a Hog Roast, and ice cream stall from Blyton IceCream, and live music from the Butterfly Party Band, both days, and the band was fantastic. There weren't many people watching which was a shame, but they blasted out some great songs, ending with Dakota, much to everyone's delight.

The weather wasnt ideal, it was cool both days, with constant cloud cover, and the track temperatures were below what you'd normally expect for an August event. But the benefit from that was more power from the engine, and more time to socialise and chat car stuff with other owners, which is what everyone did both days. Thats how it should be, and what I enjoy the most. No clicques or groups who dont talk to each other. Just everyone mixing together and enjoying themselves.

I sold the new set of new Avon HC3's at the event, which gives me some space back in the garage at last (and some cash). They're going on a single seater. I also changed the overrun fuel cut setting on the calibration, dropping the rpm from 5000 to 3500, which helped the engine produce some really spectacular flames and loads more pops and bangs. There was a big crowd over the weekend so I thought I'd switch on the crowd pleaser mode :D

So a great weekend, no issues apart from the knackered offside front Avon, which hindered me a little, but wins are wins, no matter how large or small the margins.

The trophies are great, and I received two bottles of bubbly, but most of all, I've some really great memories of an excellent weekend.

A very well deserved Thankyou to Yorkshire Motor Club. Please put some more events on.

11Aug

Car #93

I am running as car #93 at Blyton this weekend, seeded #1. The paddock plan that's been published looks a little challenging, there are building works going on at present, so space is at a premium. No hookups will be challenging. I'll have to take the petrol gennie.10Aug

Shelsley BHC meeting

I travelled over to watch the BHC meeting at Shelsley today to see the quick boys in action. I wasn't disappointed. The rate the Top 12 travel up the hill has to be seen to be believed. We met a few friends, and stayed until 4pm, and then headed home. The weather was perfect, and the track was in great condition. I took a few photos, and a couple of videos, which I'll upload to the YouTube channel later this week. The spoils went to Matt Ryder and Alex Summers, and Simon Bainbridge took the Tin Top Challenge win in his SBR Chrono. Simon was having some issues with the boost targets and PID on the Motec ECU in the Chrono, and my son Marcus helped John Hansell make some changes. He knows a lot about PID's from the racing drones that he pilots. They have to be tuned, using PID to get the best performence out of them. The changes didnt help Simon take the overall closed roof record that he was after, but at least they have some ideas for what to tune for their next event at Prescott.6Aug

Snetterton

Having reviewed the data from Croft, I've now realised why I didnt set a new PB. Last year we were working on an ExtraBoost map for the car, to give increased boost pressure; and for some reason, I'd turned that feature off, so the engine wasnt making as much power as it was last year;I had an odd thing happen on the first practice run at Croft. I launched the car, and it then selected second gear, and stalled the engine, because the upshift was too early and the revs dropped too low for the engine to make any boost. I rolled to a stop, selected first again, restarted the engine, launched again, and the second time it got away without any issues. The data does show an Up Shift was pulled, which may have been me, or could it have been the dashboard just sending a random up-shift signal over CAN? I'm suspecting human error :D

Its only happened the once, and given I dont even use the paddles to change up a gear other than when I select first for the launch, I'd say it was down to me pulling the paddle. I must remember to keep my fingers away from the paddles when I'm driving, and let the ECU drive the car.

5Aug

Congratulations

The Masters student who based his CFD dissertation on my Mygale last year, has just landed a job at the new Cadillac F1 team. I'm so pleased to have been involved with his dissertation, I'm sure he'll have a great future working in F1. Well done Henry:DThe two pieces of carbon angle have arrived from Easy Composites. So on Friday I'll hopefully have time to fit them to the side skirts, using the 3M tape, that will keep them from falling off and add the stiffness that's required. I'm off to Shelsley Walsh on Sunday to watch the British Hillclimbers in action. Fingers crossed the weather holds out.

4Aug

Two wins for Faulkner

With the low turnout at Kirkistown, Ethan won the first run off on both Saturday and Sunday, with some very rapid laps; he was running new Hoosier tyres, which are still not as good as the Pirellis run by the other competitors, but a win is a win. Plus he's the youngest ever run off winner at 22!.Smiles suffered a fuel pump failure on Sunday so took no part in either run off. Porrett (EcoBoost) only managed last place in three run offs he completed, and on Sunday, after a NTR didnt participate in the final run off either, leaving just four cars to fight for podium places. Porrett was some 10 to 13 seconds off the pace, so must have been nursing a sick car both days. On Saturday Goulding suffered a push rod failure in first practice, presumably the bumps and kerbs at Kirkistown took their toll. I also suffered a rear pushrod failure there several years ago, and only had 15 minutes to swap it out. Which I did, by myself, and I still scored points in the run off :D

In prep for Blyton on the 16th I've refitted the timing beam splitter, which needed a slot cutting out of it to clear the 3D printed deflector that is bonded to the outside of the end plates. The modification to the splitter will make no difference to it's operation.

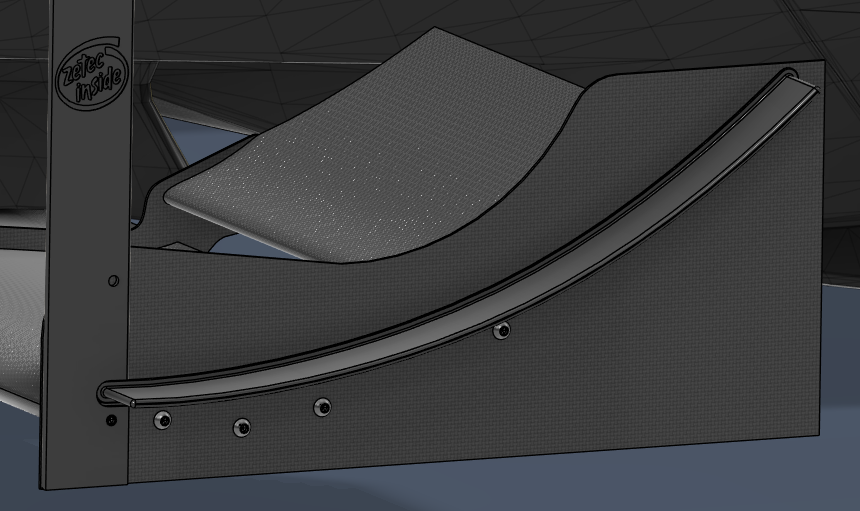

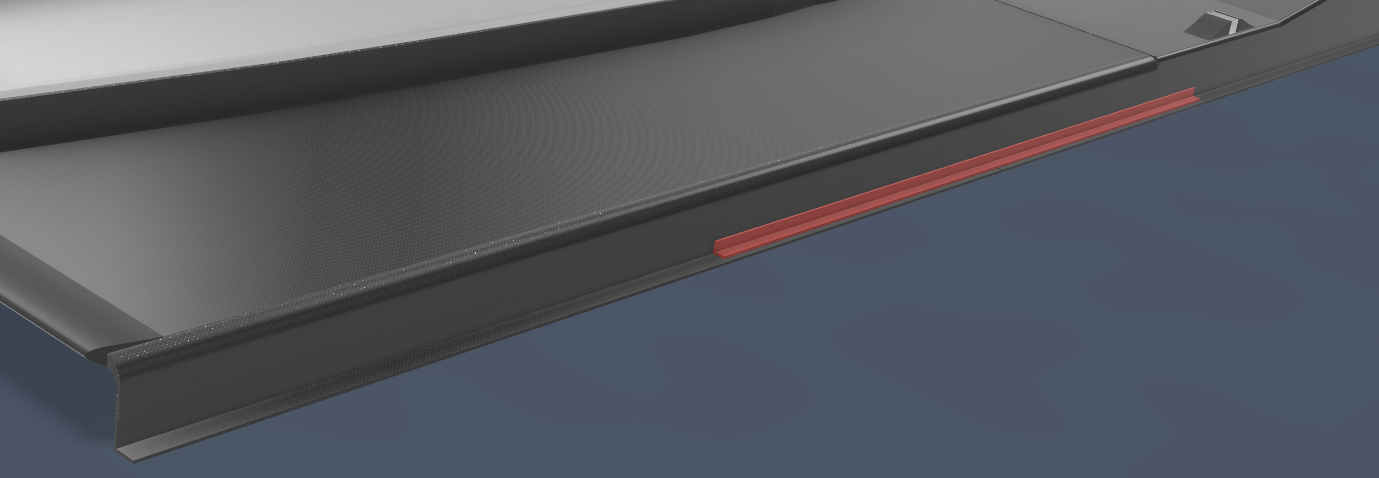

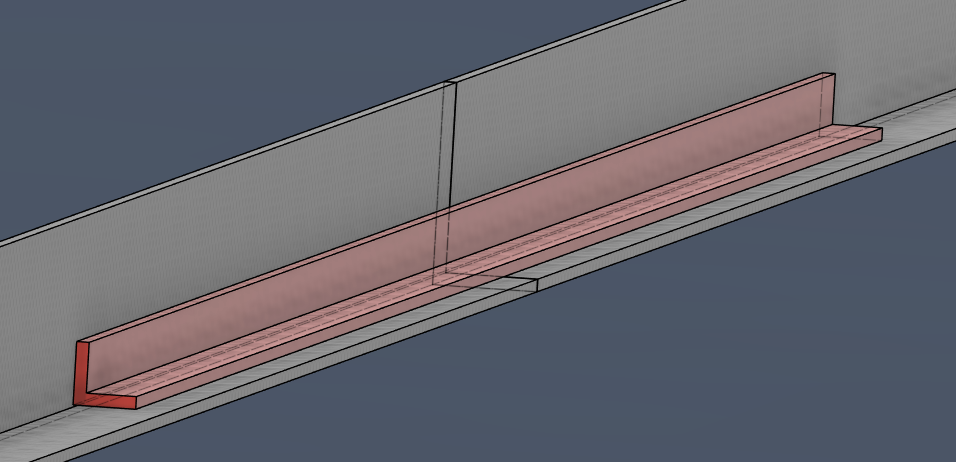

I've also got a pair of metre long 15x15x3mm right angle sections of carbon on order from Easy Composites, which will be bonded to the pair of existing right angle sections (50x25x3mm) that form the side skirts on both sides of the floor.

Because there is some lift at the leading edge of the floor (due to a low pressure above the floor), the floor is bending upwards where the two right angle sections butt up against each other. Adding the additional right angle sections over the joint on both sides of the car, will prevent that from happening again, by adding stiffness.

31July

Croft video

What a great video of me from Croft on my 80 seconds run.28July

Croft Success

I couldnt quite match my PB from 2019, I did record an 80.41s run, and my PB was a 79.32s, but in my defence my tyres are 3 years old now and the weather was a lot cooler. Excuses over, it was a great days racing on Sunday, I made more new friends, and thoroughly enjoyed the event. I did one practice and five timed runs. My best run was T4 on the freshly cleaned Pirellis, which was as hard as I dare push the car. I was running very low downforce on both wings, to see how well she handled with less downforce, and the car was very neutral. It was good to get away from the security blanket of running high wing angles. Sometimes you've just got to try these things. Had the rain come down then I would have gone back to max downforce, but although a rain shower was forecast the day remained cool and dry. Maybe a bit more downforce would have led to a new PB, but I was happy with the result. I won my class, and took FTD, and Adrian was just 3s slower in the Fensport Yaris GR. It is running 110RON race fuel, with water/methanol injection before and after the intercooler, and with 2.6bar of boost, the 3 cylinder 1600cc engine is producing in the order of 600bhp, which is transferred to the tarmac via all four wheels. It''s a stunning car to look at, and it is pedalled extremely well. He'd embarrass most of the field if he were to run at a BSC meeting :D20July

Tyre cleaning

I spent an hour or so on Sunday cleaning four of the eight tyres I'm running at Croft. Three Avons and one Pirelli, and only one of the Avon fronts is showing evidence of cold shear. I did give them a hard time at Cadwell. Once the others are cleaned I'll wrap them ready for transport.Following the intense heat at Cadwell, I checked the level of the water in the header tank, and it had dropped just below the bottom of the tank, and it took maybe a cupfull of coolant to bring it back up to the normal level. Dont forget, never dilute coolant with water in these engines, it leads to core plugs rusting and bursting, lesson learnt in 2023. Since then I've only used ready mixed coolant which contains antifreeze and anti-corrosion chemicals.

17July

Coming up - Croft sprint

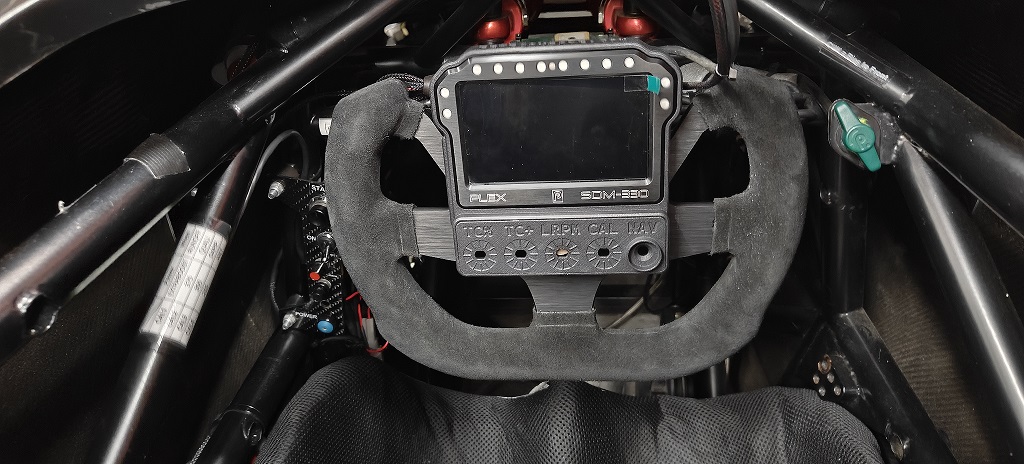

I'm looking forwards to the upcoming trip to Croft for round four of the Javelin sprint championship on July 27th. I am leading the championship, but I'm missing both the Anglesey rounds in September due to a surgical procedure I've got booked the last week in August, so the Blyton sprint in August (16th & 17th) will probably be the last time I drive the car this year. Missing the remaining rounds means I cant win the championship overall, but I'm not too bothered about that, I just want to enjoy the car and the driving.In prep for Croft I've changed the dashboard layout, to reduce clutter from the Pits screen, and increase the intensity of the LED's from 10% to 90%, I just couldn't see them at Cadwell. The 3D printed bezel worked great, and the joystick I found made it very easy to change screens. Its a very impressive dashboard, well worth looking at if you're in the market for one.

16July

Noise issues at Lydden Hill

The organisers had to alternate race cars with saloon cars at one point last Saturday, due to noise issues at the track, and that meant the fourth timed runs were cancelled. I have heard stories of residents sitting outside their homes with sound meters, monitoring the noise levels. I'm sure the track was there before they occupied their homes.Broughton took two wins, with Jones 2nd, and the rest were several seconds slower. I believe Nick Scott has now hung up his helmet, he is apparently selling his Force, which means one less driver heading over to N.Ireland in August. I reckon there's going to be just five drivers heading over this year. Easy points for those who do, 80 points for the weekend for the sixth place driver just for turning up; my money is on the local Ethan Faulkner to clean up both days.

11July

Falling attendance

Just ten drivers travelling to the next BSC round at the weekend, at Lydden Hill. Thats one less than 2024. I wonder how few will travel across to Kirkistown in August? I mean its easy points when no one else turns up. No qualifying, just drive it and net a bag of points for showing up. I wish the championship would revert back to the old points system, with Top 12 run offs.9July

Two more weekends remain

I've only got two more events to go this year; the Javelin sprint at Croft at the end of July, and the Yorks motor club event at Blyton in August, both of which I am really looking forward to. I'm not planning on racing after August, the new job is very time consuming with lots of travel, and therefore very tiring.29June

Cadwell success

I managed one practice and five timed runs yesterday, getting my time down to an 82.21s run on the old pirellis. That was good enough for first in class and FTD. This is only my 3rd visit to Cadwell in the Mygale, and only the second full dry event. The first visit in 2023 was wet, and in 2024 I managed a 82.54s run. Today I took 0.3s off that time which given the extreme temperatures I was quite happy with.The Plex dash worked perfectly, allowing me to see all the channels, and select gears using the paddles. Aside from the bonkers 30 degree heat, it was a very enjoyable day, blasting around the Cadwell Park circuit. I've still not learnt it, but I was making huge improvements, getting more and more confident. Again, swapping from the two year old Avons to Pirellis gave a big improvement in grip on the final two runs, and it was only then that I could really push the car.

27June

Cadwell this Saturday

The car is all packed up and ready for the trip over this afternoon, for the JTSS competition at Cadwell Park tomorrow. Just hope I can get a decent spot in the tarmac paddock.Plex has featured my dashboard install on their web site, it's a very impressive read.

Plex SDM-330 article

22June

Mallory Park BSC round 13 & 14

I went to Mallory Park on Saturday, to watch Ethan Faulkner pedal his OMS around the circuit, and I wasnt disappointed. He managed a 2nd place in the one and only run off in the afternoon, proving how adept he is at learning tracks. This was his first visit to the Leicestershire circuit.

It was another day beset with problems. Mallory Park just doesnt seem to lend itself to smooth running sprints over the two lap format (not when there are multiple accidents anyway). The circuit is great, but the venue desperately needs a revamp! A drastic shortage of marshals, and temperatures peaking at 29C didnt help. A crash in the morning involving a Lotus delayed proceedings by 30 or so minutes. A couple of rain showers made things interesting, and after the commencement of the T2 run after lunch, the BSC drivers had just completed their runs at the head of the batch, when a further short shower made the track very damp, sadly catching out one of the Radical drivers. As they crossed the finish line, braking heavily, the car did a 180 and then hit the tyre barrier on the left just after the Edwina chicane. The driver was carted off to the medical centre, and after an hour the organisers announced the meeting had been abandoned since the ambulance needed to leave the circuit to take the driver to Leicester Royal Infirmary for further checks.

I was sat in the cafe downloading images from my camera when I heard the impact. It sounded horrible. When I looked across the track, the driver appeared to sit for quite a while before anyone turned up. A young marshal was first on the scene, and others soon followed. The tyres on that tyre wall made short work of the Radical. I dont know how old the tyres are, but they're bound together tightly, and have gone very hard having sat exposed to the elements for many years, and they just dont offer the protection of recticel/foam barriers.

I hope the driver recovers quickly, and gets back behind the wheel again soon.

As for the eleven BSC drivers, Steve Browns supercharger failed on the Empire EVO at the end of his first practice run, leading to him missing the T1 qualifier run whilst he swapped chargers over. Steve Broughton's gearbox shat itself on the line in practice, and he also missed the T1 run, but had the car running for the one and only run off. It was good to see the new F4 EcoBoost running. It sounds and looks like it needs a lot of work on the tuning, particularly with the launch control as it often bogged down and stalled on the line. But they've only just started the journey so I'm sure they'll get it running smoothly in time.

There was another EcoBoost, the ex-Sutton car, running around at the back of the group, so aside from Smiles and Ethan, Pete G wasnt really troubled and picked up yet another win. Chris Jones had COVID, so he sadly missed the event, which he may regret later in the year. I had a few welcomes, good to see you's, and a very frosty 'youre not welcome here' from one of the more senior drivers; it's a championship with a definite PR problem.

14June

Tyres cleaned

I cleaned the Pirellis today, which are 3 years old but still have loads of life left in them. I'm going to fit the new Pirellis to the other set of rims, to replace the two year old Avons. Just trying to find someone in Leicester that can fit tyres to split rims, after the last experience where one particular shop managed to bend an outer, I'm just not sure who to take them to. I asked Graham Goodes but they declined. I may have to take a trip over to BMTR if I cant find anyone locally. Thats not too bad as they're 45 minutes away, but it'd be easier to find someone local.I'm at Cadwell Park on the 29th June, so I need to get the fresh rubber fitted before then.

Plex are going to write a feature on my 3D printed dashboard solution for the SDM-330. I've been asked to provide photographs and some notes on what I've achieved, so hopefully I'll be sharing a link to their web site in the next week or so.

9June

Extra CAN

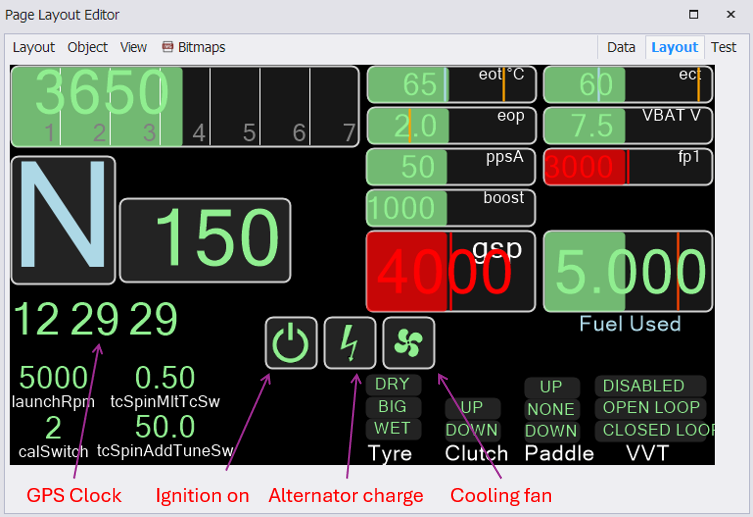

I added four more channels to the Life ECU Datastream, as it was still only sending 48 channels (48 is the maximum the Dash4Pro could work with). I've added gpsTimeHour and gpsTimeMin, as well as engineEnable, and LaunchMode.The reason for adding the pair of gps channels, is that I now have a digital clock on the pits/paddock page, so when the engine is idling and I'm either warming the engine up or sat in the car in the queue, I can a) see the time, and b) have confirmation that the GPS board has aquired a satellite lock and therefore the car will have a track map for me to download when the run is complete.

engineEnable is used for a new icon, which shows if the ignition is on or off. I had to create a flag and invert the logic, because the channel returns 0 for igntion on, and 1 for off. The reason for that is the ECU needed a 1 to kill the engine when the switch is turned off, so the ECU outputs the reverse to what you think it would for ignition on and off.

Exciting Shelsley

I dont know if you were following the live stream from Shelsley at the weekend, but the footage from the Hillclimb TV livestream was incredible. Alex Summers took the first run off win, and Matt Ryder the second. The footage can be seen here.Ethan nearly takes his first win

Ethan Faulkner, the teenager from N.Ireland, on his first visit to Pembrey, finished 2nd overall in the final run off on Sunday, beating several champions in the process. He's an amazing talent, and I look forward to seeing him in action at Mallory Park in just two weeks time. The EcoBoost is fuelled and ready......1June

Success in France for Will and Simon

I am really happy to report that Simon Bainbridge and Will Shuttleworth both had success in France at the St Goueno hillclimb over the weekend. Will's Radical SR3 is the one I rewired, for the Gen2 Hyabusa engine using the DTA S100 ECU and a donor loom from a car running a Zetec engine. Will had no issues at all over the weekend, and posted a very reasonable 1m 43s run on his final dry weather run on Sunday, before the rain spoilt the fun. Congratulations to Simon and Will on an outstanding job. When Will said in January he wanted to do the hillclimb in May, I was keen to get involved and help, and you couldnt ask for a better customer.31May

Dash upgrade completed

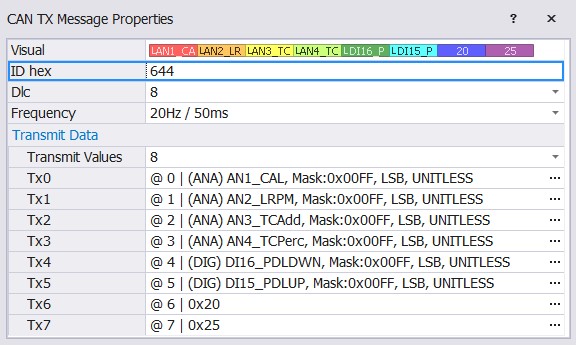

It turned out to be a very trivial change to get the ECU to recognise the data sent from the Plex dashboard. It was as I thought, that it needed a full 8 bytes of B Frame data, otherwise the frame would be discarded. With the Plex configured to send four rotary switches, plus the two digital paddles, and two more fixed values to pad the frame out to 8 bytes, I simply had to reassign the ECU IO to the relevant B Frames and it worked! Both paddles are recognised, along with all four switches. I also changed the Plex to send 0 to 11 for the 12 positions provided by the rotary switches, rather than 1 to 12, and the ECU recognised all the switch positions.I also unassigned the pair of analogue inputs on the SLAVE1 AN channels, which means I now have another pair of free analogue inputs available (via the X10 expander) which could be used elsewhere to monitor more of the engine health.

The printed bezel will be available in the Ebay shop, so if anyone else wants to use the same solution, I'm happy to manufacture and supply the parts.

26May

Connected the dash to the ECU

I had limited success connecting the Plex dash to the LifeRacing ECU. By that I mean, the dash displayed all the CAN data like I set it up to do. But the four rotary switches and the digital paddle switches were harder to setup. I'd asked Plex if the dash supported B frames, and it did. They provided the instructions how to send the LSB using a bitmask of 0x00FF. I set that up, but it wasnt receiving the data. To cut a long story short, the reason why was the ECU was discarding the B frames it was receiving, because I hadnt set the Plex dash to send 8 bytes. The ECU must see 8 bytes otherwise it discards the frame. Anyway, now I know that I've set the Plex up to send 8 bytes, and I'll try it again on Friday when I get back in to the garage again.

Because I've left the 9-way D-Type connector fitted on the CAN BUS, I can still plug the Dash4Pro display in at the same time as the Plex dash (which is connected using a Binder plug/socket) so that allowed me to display the frames being seen on the CAN bus. Very useful for debugging issues.

The BARC Midlands round at Snetterton in August has opened, and its another whopping £370 for the two days. Not quite as expensive as the Mallory Park round in June, but at least with Snetterton, you'll get more than two runs a day!

16May

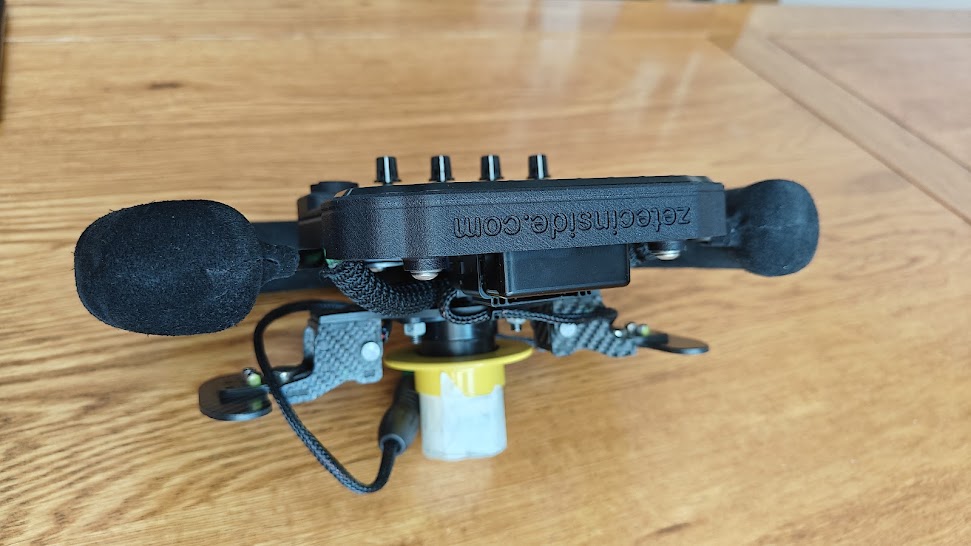

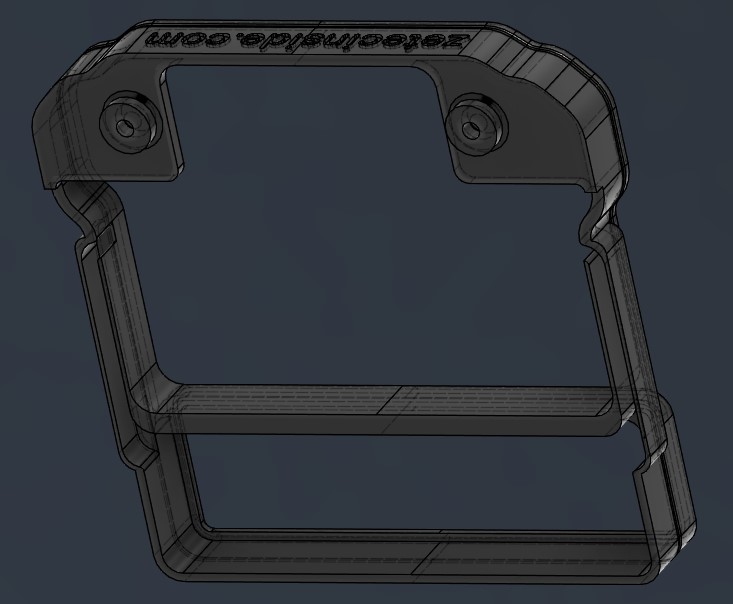

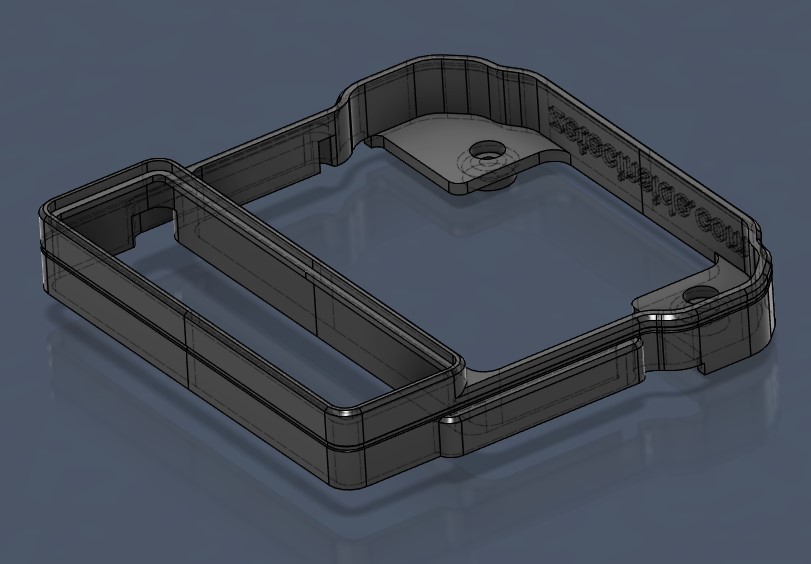

Mk3 printed Plex dash bezel

The final version of the printed bezel was waiting for me when I got home on Thursday, so I didnt waste any time in taking the steering wheel apart and fitting the quick release boss and other parts to the new wheel. I think it looks great. I've just got a few wires to fit and it can be plugged in to the car for testing :DLink to the Youtube short.

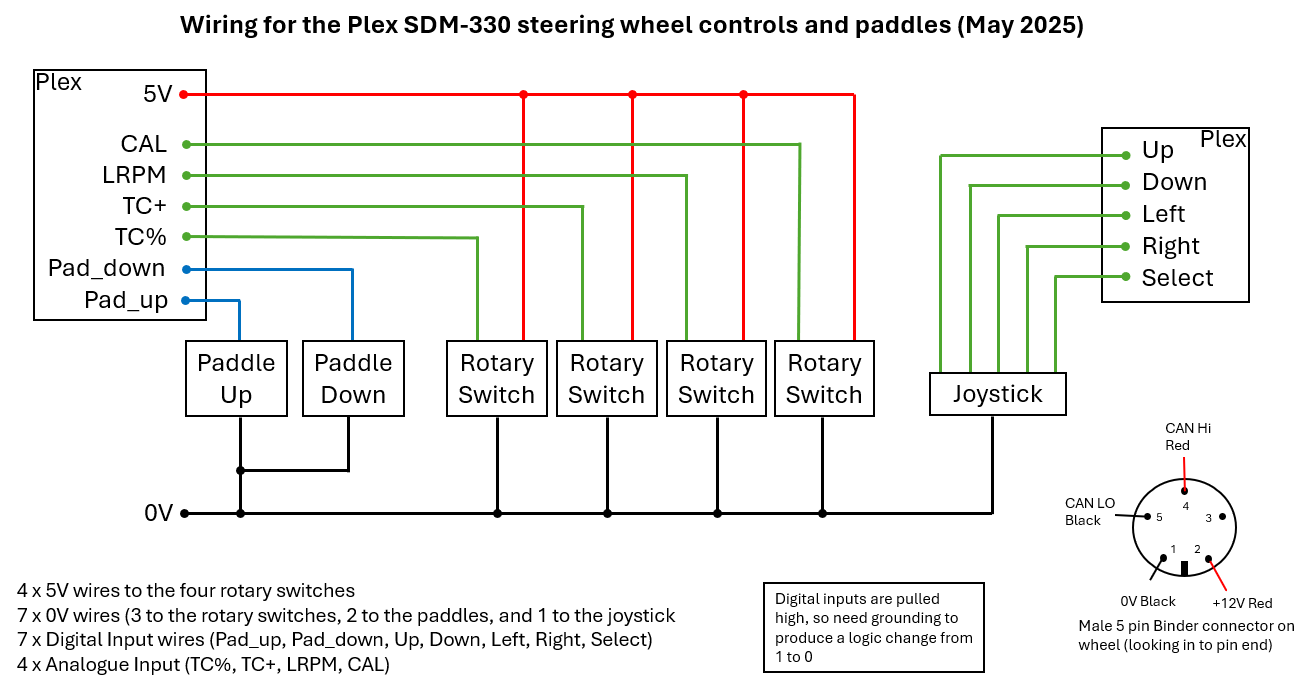

This is the schematic for the wiring that I need to produce to connect the four rotary switches, the joystick, and the paddles, to the Plex connector.

11May

Blyton success

I enjoyed myself sprinting at Blyton on Sunday, on the Eastern layout. Steve Miles and Martin Pickles (both BSC drivers) were both entered, but Martin had to withdraw and miss the event as he wasnt feeling well on Sunday morning. Get well soon Martin. Smileys ageing Van Diemen has had a lot of updates, some are working better than others. So he was my main (and only) competition, would he run the brand new Ultrasofts that he'd stashed in the trailer?I had a new silencer fitted, which I was hoping would knock a couple of decibels off the sound level, so I wouldnt trip the sound meter. After I returned from my first timed run, I was warned the sound level had broken 98dB. So the previous event it was 95dB, and the addition of the silencer made the car twice as loud? OK, so I removed the silencer, and dropped the auto-gear shift rpm for 3rd gear to 6000rpm, to act as a short shift. Still on the cleaned Avons, I did the first timed run, full of trepidation. Had I tripped the sound meter? No, I was below 95dB this time. How does that work? Why would a silencer double to sound pressure? Anyway I spoke to Kev Theaker, and he said keep left off the start line, to put a couple more car widths between your car and the sound meter, which I did, and for the next four runs, I had no issues with noise.

Smiley was running on old Pirellis, and I opted for the 3 year old Pirellis for my T3 run, and on that run I recorded my quickest time of 56.65s. For all the other runs I was in the 57's, once the Pirellis had had their first use, their grip levels fell away, but at least I was consitently faster than Smiles. His best run (his sixth run which I elected not to do) he managed a 56.72, so I beat him by 0.07s, to take first in class and fastest overall.

No drama's today, I did reconnect the water sprayer and used iced water, which kept the air charge temperature below 50C, which wasn't bad considering the ambient temperatures were around 25C.

7May

Dashboard housing update

I've made a final push to get the dashboard housing completed, by mirroring the chamber I added on the side for the wires, so there is now a chamber on both sides of the housing. This will give me more capacity for wires to run down to the front panel for the switches. I drilled the steering wheel at the weekend, for the Plex dash to attach to it, and the dash fits nicely inside the housing, against the aluminium wheel centre.

3May

Horn replaced

It was very easy to swap the faulty car horn on the beemer. Jack the car up, remove the wheel, remove the inner wheel arch lining, remove the faulty horn, and after fitting the new one, the process to put it all back together again took another 10 minutes. Cheaper than paying the BMW dealership to do it.2May

New job

I started a new 12 month contract on Monday, so now I'm working Hybrid so I'm spending three days a week at my clients office in Manchester, and two days at home. Its been a busy first week, with an unexpected trip home on Tuesday afternoon to return again Wednesday morning, so the mileage is double that of a normal week, but its good to get back on the road again, and back in to an office environment.I am now working as part of an Agile team, and getting to grips with daily SCRUMs and two week Sprints. Totally different mindset to the previous client I worked with.

I had the 335D serviced last week, in anticipation of the increased milage I'm going to be racking up. The last service was at the end of 2021, as the car had only travelled 14,000 miles in the past 3.5 years. So it was just a basic oil and filter change for £310. The dealer said one of the horns had stopped working, the car has a pair, a 400hz horn and a 500hz horn, and the 400hz one had gone silent (a common fault apparently on the 3 series). So I ordered a pair of new ones, made by Hella, from Autodoc, and they've arrived, ready for fitting this weekend.